1968 Shelby Cobra Menu

| Who was Carroll Shelby? | Serial Numbers | Color Codes | Shelby Cars Production | 68 Specs | 68 Prices | Special Features |

The 1968 Shelby Mustangs started a new chapter in the Shelby car story. Production of the cars was moved to AO Smith in Michigan. The earlier 65-67. cars were modified at Shelby American in Los Angeles, CA.

The lease was expiring on the two hangers that housed Shelby American at the Venice, California, airport. Sales of Shelby Mustangs were up in 1967, six times more than 1966, promising an even better 1968. More assembly space was going to be needed to build more cars. The increased sales also compounded the problems of obtaining a large enough supply of quality fiberglass to modify the cars.

John Kerr and Fred Goodell

Ford was more than a strategic partner to Shelby American by this time. In 1968 Ford was calling most of the shots. John Kerr, was sent to Los Angeles in 1967 to be the new General Manager of Shelby American. Once he settled in, he called Fred Goodell to convince him to also come to LA. Fred was an on and off again employee of Ford.

Goodell had no intentions of moving to LA. But Kerr convinced him to fly to LA and check out the situation at Shelby American. After a week of visiting, Goodell was called into Shelby’s office and offered the job of Chief Engineer. Goodell accepted the job in 1967 to sort out the issues with that production year. He continued as Chief Engineer until 1970.

Both Kerr and Goodell were fully aware of the issues facing Shelby Mustang production in 1968. The lease was up, obtaining quality fiberglass was a big issue and the operation needed a larger, more experienced production staff to assemble the greater demand for 1968 cars. Each of these issues was a big problem in itself.

During a Kerr and Goodell conversation, Kerr mentioned that he had a “buddy” back in Michigan that might have an answer to all three of these problems.

AO Smith Ionia Michigan

Smith Plastics Division was a subsidiary of A.O. Smith in Ionia, Michigan. It had been supplying quality fiberglass bodies to GM for it’s Corvettes. In fact, there was a two story. full production line at the A.O. Smith facilities. Kerr knew that GM didn’t renew the contract so the production line was setting idle. And Kerr also knew George McFarlane, sales manager at Smith Plastics.

Kerr and Goodell went back to Michigan and met with McFarlane and the AO Smith people. They were more than eager to take on the Shelby Mustang project.

Matched Metal Molding Fiberglass

A key selling point to this deal was the way Smith produced fiberglass parts. Prior suppliers used an open mold process. The molds supplied a finished top side and a rough bottom. Plus this process resulted in a random finished product, that did not give a uniform, consistent fit. And to make it worse, multiple fiberglass vendors had to be enlisted giving very inconsistent quality. This was a big problem with the 1967 cars. Practically each fiberglass part used on the 1967 cars had to be hand fit to the cars, a time consuming and more costly process.

Smith’s process was different and promised more quality and consistency. This approach was real common in the plastics business. It was called “matched metal molding.” Two metal molds were used yielding a finished surface on both sides of the part. This process promised not only consistency in fit, but also a stronger part. After the issues with the 1967 cars, this no doubt looked like a great answer to one of those three problems.

After a series of meetings, a deal was reached at the end May 1967. It was finalized a few months later. Smith was going to be responsible for making the fiberglass parts, painting those parts and then installing them plus the external badges, gas cap and grill trim on the Mustangs.

The other major change was to have Ford’s Metuchen Assembly Plant in New Jersey supply the Mustangs rather than San Jose, CA, Ford plant. This factory had more Mustang assembly capacity than San Jose. The decision was also made to have the cars shipped by rail without hoods or trunk lids since they were going to be replaced anyway. But it was going to take two days to get the cars to Ionia, so dummy hoods and trunk lids were installed to protect the cars in transit. These parts were to be returned to Metuchen to be used on the next load.

Shelby American was split into three pieces. The Shelby Racing Company was moved to Torrance, California. The Shelby Parts Company started out in Torrance, California, but was later moved to Michigan and renamed Shelby Autosports. The third piece was Shelby Automotive, Inc. assembly operations were moved to A.O. Smith’s large facilities in Ionia, Michigan, to oversee production. Ford owned the name COBRA. Shelby Automotive was to be based in Livonia, Michigan.

The 1968 Shelby Cobras were designed by 1967 Shelby buyers. Luxury and comfort were a lot more popular than no frills race options that year. By compromising the sporty cars of the first two years, the car would appeal to a much larger market. And sales were expected to increase.

So the 1968 Shelby Mustang was even targeted at an older buyer who wanted a street cruiser with some comfort, rather than a rough riding race car. There was little competition from Ford or anyone else for GT cars like the Shelby Mustangs so 1968 was expected to be a great year. The 1968 Shelby Cobras were offered as a small block GT 350, a 428 GT 500 and mid year a Cobra Jet GT 500KR. (Read about these models on their respective pages.)

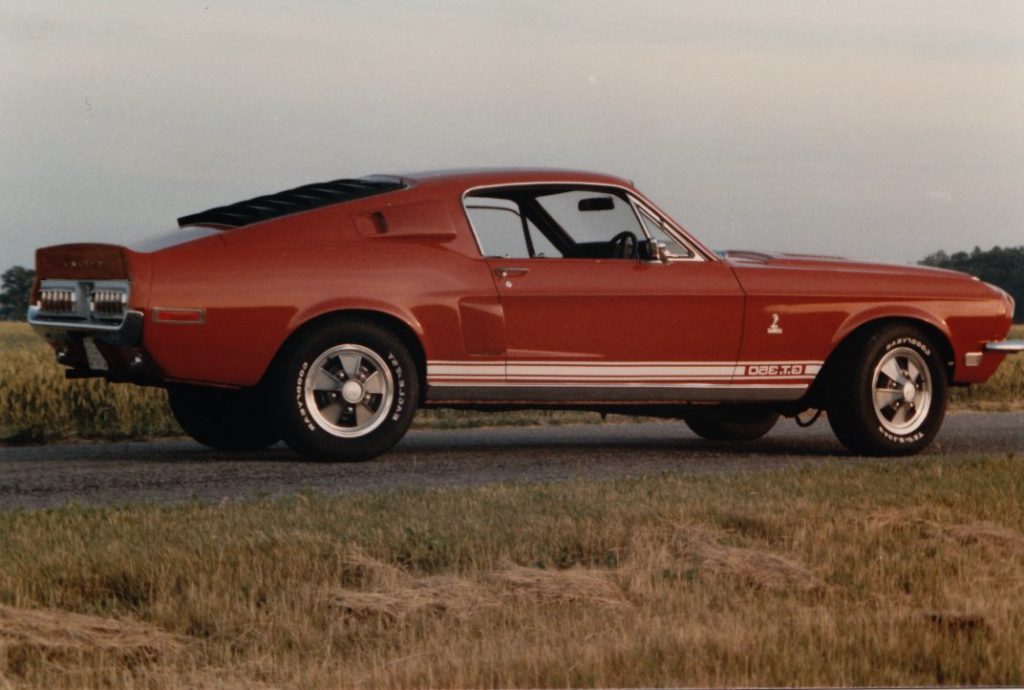

The ’68 Shelby Cobras were basically stock Mustang GT’s much like the 1967 model. The body of the 1968 Mustang was little changed from the 1967 so only cosmetic modifications were made over the ’67 Shelby Mustang. Basically only the front end and the tail were changed and a new Cobra emblem was used.

The hood scoop on the ’67 made too much wind noise, so a hood was used with a scoop almost the width of the hood. Two rows of louvers were cut across the top of the hood to allow air to exit through the hood. The rear edge of the hood had a black decal that gave the appearance of opening and exit for air. The hood was held down with a stock Mustang release latch and a pair of Druz fasteners that twisted to lock it in place.

The whole front end of the car was fiberglass. The air inlet to the radiator was much larger than the 1967 style. The opening was trimmed in chrome. Shelby had to ask for special permission of the government to do that to the car. Something he had done before.

The first ’68 Shelby’s came with Marchal driving lights inside the opening. After some problems and customer complaints, the Marchals were replaced with Lucas lights. All early ’68 Shelby’s were recalled and their driving lights exchanged.

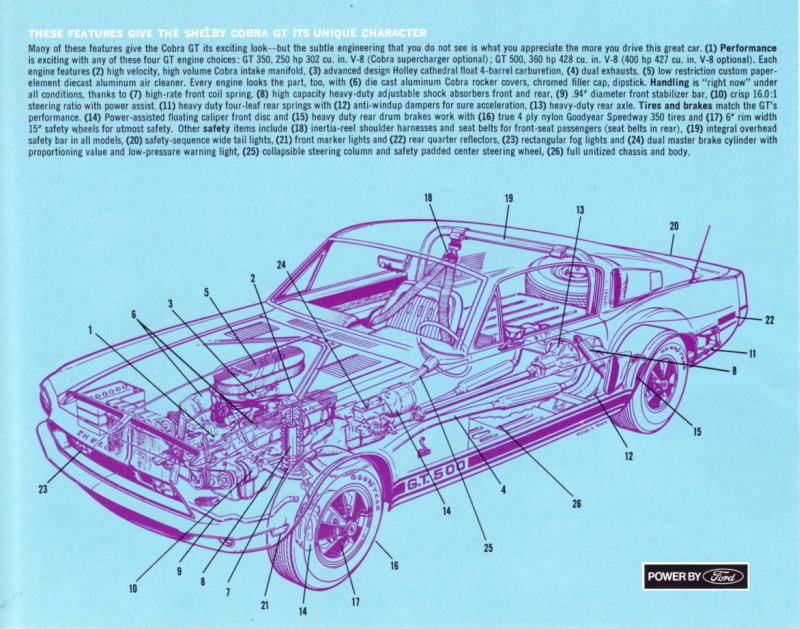

The side scoops, borrowed from the Ford GT 40, remained but only the top ones being functional. A padded roll bar was welded in place with an inertia reel aircraft shoulder harness fastened to it like the 1967 model. Side reflectors were required on all cars by government regulations. The early Shelby’s had a rectangular bezel bolted to the rear quarter panels with a small raised, border around the reflector. Later in the year the panels were flat with oval reflectors. The tire well lips of the fenders were trimmed in chrome strips.

The upper and lower side scoops were taken directly from the GT 40. The GT 40 versions both were functional. The top scoop was to vent the cockpit, the lower one directed cooler air to the rear brakes.

At the rear of the car was a molded fiberglass trunk deck lid with an integral rear ducktail spoiler, continued from ’67. This too was borrowed from the GT 40. On the side, on the lower rocker panels were white GT stripes indicating GT 350, GT 500 or GT 500KR.

Off the shelf 1965 Thunderbird taillights replaced the stock Mustang units. Trimmed in chrome, the sequential taillights blinked across what looked like six individual lights. The Shelby version was all chrome as they are on my car above.. A fiberglass panel was added to support the taillights. The rear valance was stock GT Mustang. Under the valance exited dual exhaust tips with two large pipe-in-a-pipe tail pipe tips. Note the Shelby pop-open gas cap with the Cobra emblem and the letters SHELBY across the rear spoiler. The letters S-H-E-L-B-Y were also placed across the front of the car, just in front of the hood.

The stock Mustang pop open gas cap was replaced with a Shelby Cobra chrome cap. (This picture was taken before I removed the black paint from the Chrome tail light frames.)

Inside the cockpit, the interior was stock GT Mustang. Wood grain veneer graced the doors and the dash. A Shelby unique wood grain console carried a set of Stewart Warner oil pressure and amp gauges to supplement the stock ones in the dash. The padded armrest was embossed with a large coiled snake. The interiors came in black or saddle. Mandatory options were: tilt away steering column, a fold down rear seat, power steering and power assisted brakes.

Here is a page that compares the exterior of the Shelby Mustang to a stock Ford Mustang, click here.

The deluxe interior was all vinyl with deluxe custom weave Mustang bucket seats, full loop pile carpet, and electric clock. The center console was custom to the Shelby Mustangs. The tach was an 8,000 rpm with a 140 mph speedometer.

A padded roll bar was added to all the fastback cars. It is welded to the floor in the back. The aircraft, inertia shoulder harness is fastened to the rollbar. (This picture is of my car with rear louvers.)

Padded Roll Bar in my car. Black interior. Custom Weave Deluxe seats. Fold down rear seat.

The New Ford 302 Engine

The 1968 GT 350’s were powered with Ford’s new 302 4V. Gone was Ford’s infamous HiPo 271 HP, 289. An aluminum, high velocity, high volume, Cobra hi-rise manifold handled a Holley 4 barrel carb. The very early cars carried the stock cast iron because the factory couldn’t get an ok on the emission tests using the aluminum hi-rise and Holley carb. These cars were recalled when the hi-rise was given the emissions ok. The Holley was an advanced design cathedral float four barrel. The Shelby version of this engine was rated at 250 HP. The stock Ford 302 four barrel engine was rated at 230 HP.

Shelby American did offer a unique option for the small block version. You could get a Paxton supercharger which increased the horsepower by 40% to about 335 horse. Big block horsepower from a small block Ford. For a few dollars more though, the buyer could get a GT 500, so very few superchargers were actually installed.

The factory offered performance and dress up optional parts like headers, Koni shocks and shift knobs. Ram air was standard on the GT 500KR, an option on the GT 350. (See the KR page for more information.) Also on the engines were die cast aluminum Cobra valve covers, chromed oil filler cap and dipstick. The hood was fastened in place with Druz, turn and lock hood locks. The same hood locks were used on the 1969 Mustang Mach I’s.

Steel Rims and Wheel Covers

The cars all came with standard 15″x6″ steel, heavy duty steel rims and hub caps. The hub caps were mag wheel like with a Shelby Cobra emblem in the middle. (See the hubcaps on the image below.) The same type 10-spoke wheel offered as an option at the end of the ’67 production run. The 15″x7″ wheel was a special Shelby only mag. (The 1968 aluminum wheels will not fit 67 cars, though.) The rims carried four-ply polyglass Goodyear high performance tires.

An update on the prior paragraph: I recently found out the reason the steel rims and hubcaps came on ALL the 1968 Shelby Mustangs was due to a problem with the Kelsey Hayes front discs. The dual piston KH discs had a problem so the cars were given a larger, single piston disc. The 15″ ten spoke rims wouldn’t fit over that single piston KH. When I put the 10 spokes on my car, sure enough, the rims rubbed the brake piston. Hitzeman and I took a grinder to the rims to clear the KH discs.

During the 1968 production year, as usual, changes were made on various things. The early cars received different lower scoops, ones with an extra highlight on the front edge of the scoop. (My GT 350 is an early one and actually has ’67 like scoops.) Some ’68 cars came with dual serial numbers. Apparently the plan was to use a numbering system similar to the ’67 method. But it wasn’t done and the cars numbers got a unique Shelby number at the end of the Ford number. California cars did not have functioning sequential taillights, due to state laws. The other interesting glitch is the door sill plate on the early cars said “Shelby American, Inc.” Later cars got a plate saying “Shelby Automotive.”

The base model for the Shelby Mustangs was the GT Mustang with heavy duty suspension. But there were some Shelby differences. The coil and 4 leaf springs were special use, and unique to the Shelby Mustangs in the ’67 & ’68 models. The springs were designed to to be more firm as they compressed under stress but still allowed a respectful normal ride. Anti-wind up rear spring dampers were added for better acceleration.

The front sway bar was thicker (.94″) than the GT Mustang and adjustable, Gabriel shock absorbers replaced the stock ones. The cars came with power-assisted floating caliper front disc brakes and heavy duty rear drum brakes. The power brake system was a dual master cylinder with a proportioning valve and low pressure warning light. The power assisted steering had a crisp ratio of 16:1. The rear axle was heavy duty. The ’68 Mustang came with a collapsible steering column and a safety padded center steering wheel.

Convertible Offered

A convertible model was offered for the first time in 1968. A prototype was built in 1967. It was redone as a ’68 even though the serial numbers on the car were ’67. This particular car was stolen from Shelby American, stripped, recovered then promptly restored as a ’68. This car was used in company brochures and PR materials. The convertible came as a GT 350, GT 500 and a GT 500KR. Unique to the Shelby convertible was a large roll bar with D-rings said to be included to hold a surf board.

Why Named Shelby Cobras?

So why were these Shelby Mustangs called Shelby Cobras? The production of Cobras had stopped in 1967. Shelby had intentions of building Cobras again. Ford now owned the name Cobra. The desire was to keep the name Cobra out in front of the public. Thus the ’68 Shelby Cobra Mustangs were called Shelby Cobras. The word “Mustang” is not found anywhere on the cars.

A side note: A couple of other special interest Fords were also modified at A.O. Smith. Dan Gurney XR-7G Cougars with 427 engines and ’68 Ford Thunderbirds with power sun roofs were completed there.

1968 Shelby Mustang Advertisements

Here is a link to the collection of magazine ads from 1968, click here 1968 Shelby Mustang Ads & Brochures.

John Chun

John was hired in 1967 to finish the design of the ’67 cars. As soon as the ’67’s were done, he started on the ’68 cars. I met John at a car show in Chanhassan, MN. he walked up to me, pointed to my Shelby Mustang and said “I designed that car.” You can imagine my surprise at hearing those words in of all places Chanhassan, MN. He took me to the rear of the car and pointed at the tail lights. “65 Thunderbird tail lights. I picked them out,” I met with John numerous times before his cancer got the best of him. He told me a lot of great stories. Read my John Chun pages in this web page by clicking here John Chun – Designer of the 1968 Shelby Cobras. John gave me copies of his original sketches which are on this page.